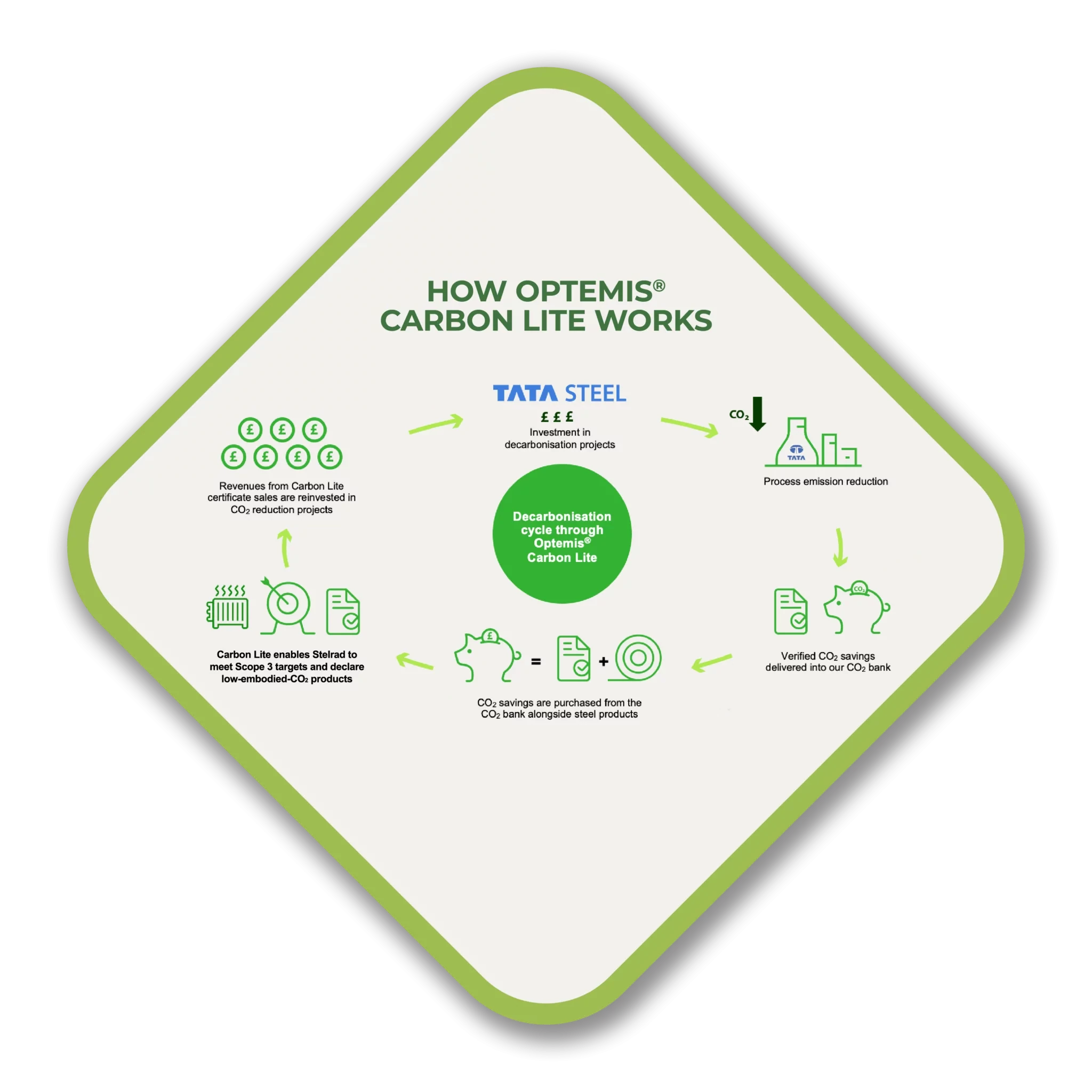

Tata Steel’s continued commitment to decarbonisation include the adoption of Science Based Targets (SBTi) to put their plan on a science-based trajectory, with a reduction in their CO2 emissions of up to 80% by 2035 compared with a 2018 baseline. Tata Steel plans to completely overhaul their main steelmaking technology within this decade.

This means reductions in CO2 emissions in this insetting scheme can be passed on to Stelrad, enabling Stelrad to also achieve immediate Scope 3 emission savings.

All revenues generated by the ‘green steel’ process are reinvested to fund additional projects, thereby generating further CO₂ savings to be verified by leading assurance organisation DNV (Det Norske Veritas). These projects ultimately speed up decarbonisation efforts within the UK.

The CO2 savings generated are deposited in a ‘CO2 bank’, the mechanism of how Tata Steel operate the ‘CO2 bank’ are also audited by the same 3rd party. DNV, which is a leading verification and certification authority is carrying out this work.